Kitchen Knife #3 - Fujiwara 270mm gyuto restoration

- Nathan Lee

- Sep 10, 2022

- 4 min read

Updated: Sep 26, 2022

By Nathan Lee - KIRU Sharpening - 10.9.2022

I purchased a batch of used/vintage knife from Japan recently and this knife is the largest knife in the batch at a whooping 270mm edge length, 51.5mm blade height, and 236g(quite light for western handle blade). After doing some research I believe this is a Fujiwara Kanefusa and made by SK steel, around 59-60 HRC.

Despite the scratched up and rusty condition, the knife has great geometry and better fit and finish compared to some of the other knife with a higher price tag, the spine and choil are fairly smooth and handle is attached to the tang decently.

Like some of the western handled blade, the balance is slightly towards knife's handle.

Before condition

I should have taken more pics, I feel like it goes to all the cleaning up jobs I've done

Choil shot/handle/balance shot

After condition

Although the knife looks like it's in bad shape, the repair/restoration isn't too difficult or complex, and most importantly the blade is very straight(if it's bent/warped, it would require a few more steps and specialised tools to fix and personally don't have experience straightening a mono steel blade), I approached the restoration with the following procedure

Rust removal

I used my Dremel (with coarse sandpaper drum attachment) to clean up some of the deeper rust, I have a feeling I could get away with some steel wire brush or even by hand sanding(RIP shoulders), the sandpaper drum attachment leaves some deeper dent on the blade and it took me a while to sand it down with a grinder and sandpaper combo. For future reference I will use lighter duty abrasive to remove the rust.

Chips removal

After removing the rust on the blade I noticed that part of the edge has became very fragile, I could literally use my finger to flick off the material and as in result... a chip was born.

I used the grinder to remove that little chip and some of the fragile metal on the blade, took me about 5 minutes.

Addressing thickness of the blade (especially after chips removal)

In my humble opinion, after a chip is removed on a blade, it's necessary to remove some metal behind the edge to maintain the blade's geometry, the blade doesn't have to be a zero grind to cut good(zero grind will also causes the knife to chip very easily) but would be nice to have a seamless transaction from primary edge to secondary edge (instead of having a set of big shoulders behind the primary edge).

As mentioned before, this blade has a decently thin geometry to begin with despite it's age, I didn't have to do much work with the coarse stone, that was nice.

Stone is Suehiro LD 180 grit.

Sanding handle

Nothing fancy with the sanding, all I did was following 120 to 1000 grit sandpaper to make the handle looks a bit nicer than what it was.

I did however look into the installation of western handles, it's definitely something I want to get into later down the track, would be nice to have a stabilised burl or iron wood handle for my TF from Morihei(which has a way worse handle instalment compared to this Fujiwara despite being 4x of the price lol.....).

Scratch removal

I did belt finish on this one because I thought it would be easy as hell (still easier than no scratch mirror), but it wasn't! it takes a bit of skill to get the uniformed finish, slight hollow on the blade and the little dent I created with my Dremel made it harder than it was, also I found the angle placement (between blade and the belt) is very important, if the angle isn't consistent, the belt will end up grinding on the wrong spot of the blade then create unwanted new scratch pattern.

The line finish is actually a lot harder than it looks, especially beyond 600 grit, however, it does save your shoulder and elbow from moving back in forth and gives you new knife feels.

I have purchased some Scotch Brite belt to clean up some final scratches and I do find the finish looks cleaner than the 600 grit sand belt, the scratch depth the Scotch Brite are a lot more shallow than sand belts.

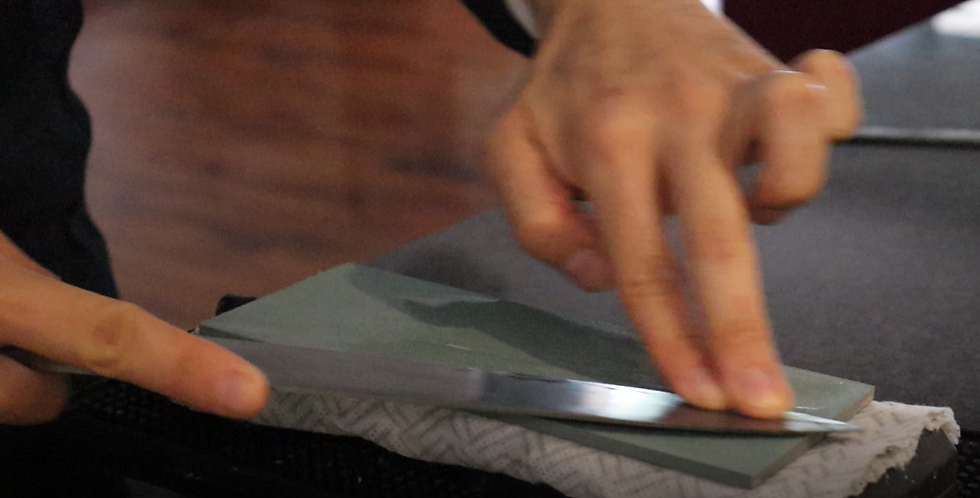

Edge sharpening

Stone progression:

I follow the progression of Shapton glass 320, 500 and Aizu - personally not a huge fan of 1000 grit stones and tend to skip them, I found the 1K are a bit redundant in between 500 and 2000-2500, and I always follow this progression of 500->2000->4000 or whatever, maybe also because the 1K I like are always over or under 1K- the Shapton pro 1000 and Cerax 1000, I did have a King hyper and Nanohone 1K but I didn't like the feel of them so I never consider to put them in progression, for me, the feel is always more important than speed or other different factors.

Finishing stone:

The Aizu is a new purchase and I think the stone is approximately 2000-3000 grit, I have to say, most Aizu I've tried feels very similar and you sort of know what to expect when you purchase an Aizu, they are not very muddy, produce good edge and have similar feel/smell.

Personally for double bevel blades I don't like going over 3K, so I stopped there.

Steel:

I have very little experience with the SK steel - just one 210mm Yanagiba/Fuguhiki, that knife takes a hell of an edge, and very easy to sharpen, don't know if the edge could last that long because I am always touching it up with 8K stone/natural after 2 or 3 uses at home, it does patina fairly easily.

This Gyuto has a good ability to take a sharp edge, it didn't take too much effort to get a shaving edge, of course the great geometry has a big contribution in this regard!

Video

Tags: Restoration, knife sharpening, knife restoration, youtube video, sharpening knife

Comments